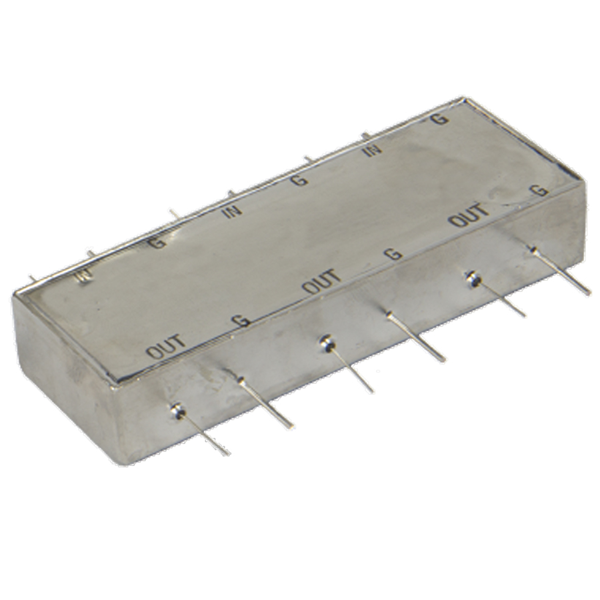

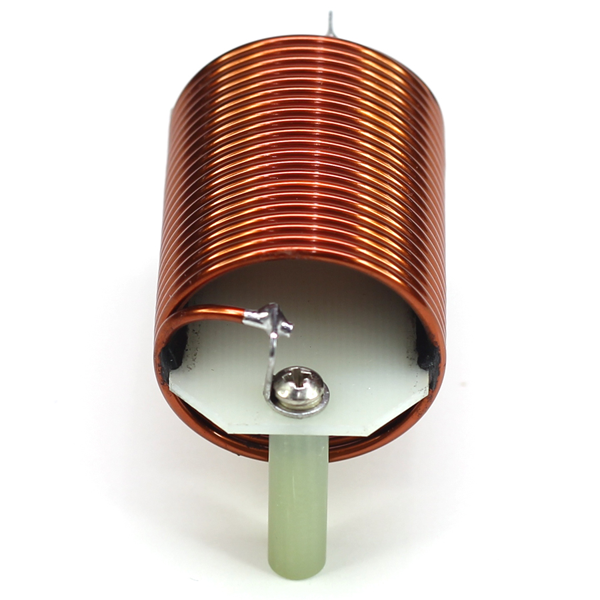

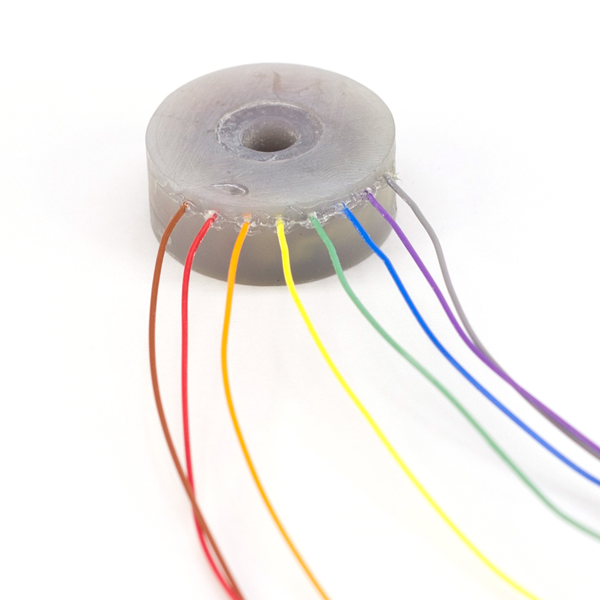

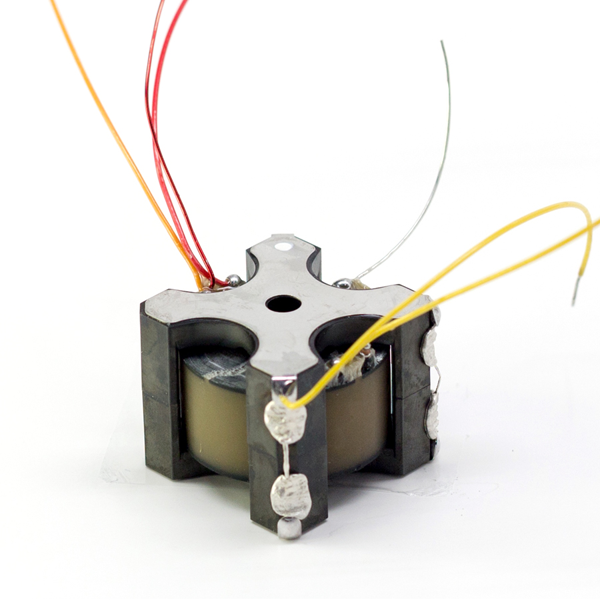

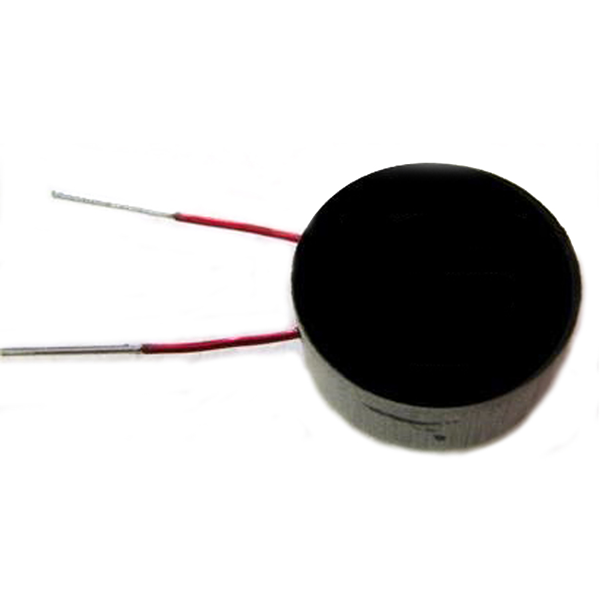

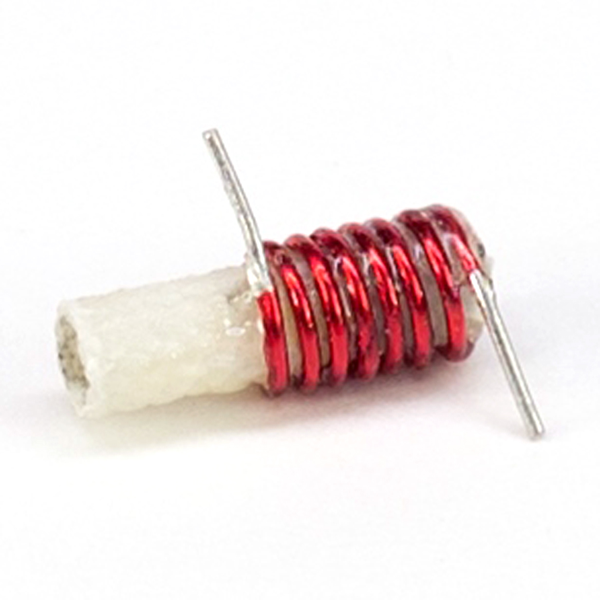

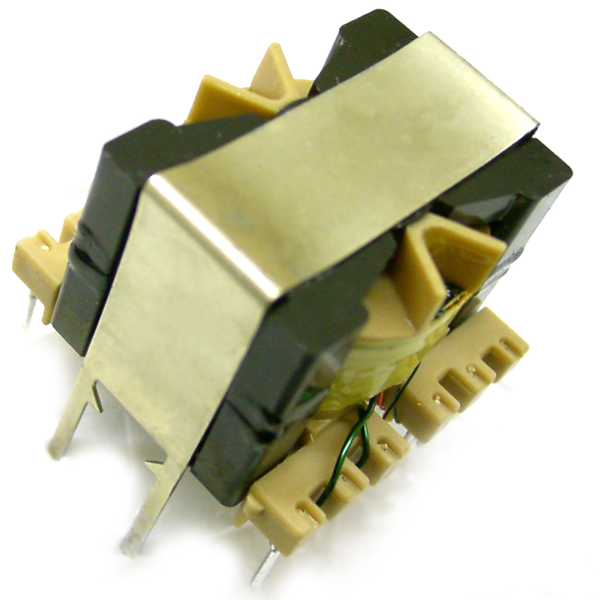

At FRC Corporation, we’re capable of designing and manufacturing custom transformers and coils for both military and commercial applications. Our experienced engineers and technicians can provide design, prototyping, winding, and impregnation, encapsulation, marking, and testing services. We can build custom wound magnetic components with core types such as toroid, pot core, planar, baluns, rods, and bobbins. Our designs feature ferrite and iron powder materials including MPP, high flux, kool mu, carbonyl, and phenolic. Our custom transformers are capable of achieving operating frequencies between 400 Hz to 1 GHz, with output power ratings of less than 1 KW. They can also be manufactured to accommodate all secondary voltage ranges.

Our high-quality products are integrated with either through hole or surface mounting schemes. Depending on the customer’s connection requirements, they can be designed with either self-leaded, service leads, or pin-type terminations. Our 1 million sq. ft. facility is geared for mass manufacturing; capable of building hundreds of parts simultaneously in order to meet any demanding supply chain requirement. All of our products are manufactured from the ground up and we have the capability to incorporate virtually any design option required by the customer. Every transformer and coil undergoes an intensive inspection process using state-of-the-art test equipment, CMM, and a wide range of measurement tools.

Our work is also backed by our own internal quality inspections and documented guidelines. We continuously check and verify our products. In addition, each facility fields a quality team that is responsible for its own continuous audit management. Since 1977, we’ve supported a wide range of industries including aerospace, automotive, medical, and telecommunications. For more information on our custom transformers and coils, please contact us or click the button below.